Just before Christmas 2016, a Scottish-based team of volunteers headed out to Cyprus. We were on a mission to repair the vulnerable church of Apliki before the January rains set in.

The team was composed of Triona Byrne, Declan Cahill and Gethin Harvey from the Society for the Protection of Ancient Buildings, builder Diane Thomas and me. We had been asked by the local Cypriot community to inspect the arch and work on emergency repairs – it was in imminent danger of collapsing.

The state of the arch before consolidation works from inner face of the church. Credit: Martin Clark

Where we went

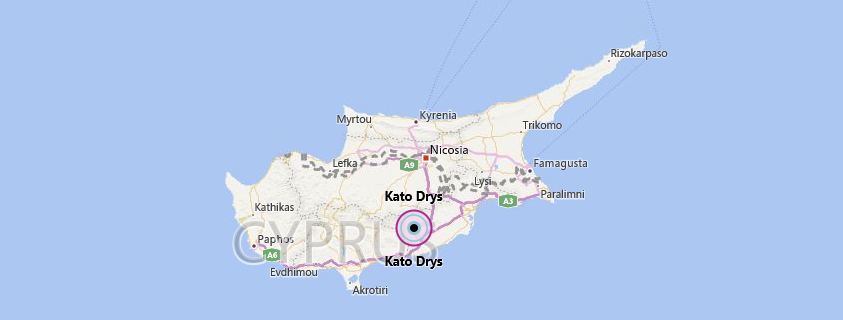

The site is located in Kato Drys, a mountain village on the eastern edge of the Troodos Mountains in Cyprus. The arch is a local landmark and is all that survives of an otherwise ruined chapel, part of one of the lost Venetian villages that existed before the Ottoman Empire invaded Cyprus.

Kato Drys location. Bing Maps.

What we did

The team evaluated the structural integrity of the arch and developed a plan for re-building it from the inside. We realigned the collapsing face with a ratchet, and consolidated the stone with a mix of lime and earth materials. We built a basic kiln from recycled materials scavenged and donated from the surrounding area, burning local limestone to produce quicklime.

SPAB scholars evaluating the state of the arch.

We mixed this quicklime with sand and earth to make hot-mixed mortars, which we used to carry out the repairs. We gained experience of producing of lime mortars from first principles, and demonstrated our methods for the local community.

Left to right, Martin Clark, a local contractor visiting the site and Panayota Demetriou, on the dismantled temporary lime kiln.

From photos provided before our visit, I already had a suspicion that the core of the arch may have been earth mortared. This was quickly confirmed once we got to the site. Because of this discovery, we did think about only using earth-based mortars in our repair work. However, because of the very precarious state of the arch and the risk that the mortar could be washed out by the impending seasonal rains, we decided to use a combination of hot mixed lime and earth mortars to make the arch more resilient.

Already burned limestone, dismantling the kiln.

Testing and proving the exothermic reaction on the Limestone as we apply water, becoming hot lime.

We worked hard for a whole week, and were rewarded by being able to successfully remove the temporary supports and expose the beautifully proportioned arch. Preparing the materials and mixing the mortar on site showed us how resilient and forgiving lime and earth materials can be, and how easily local materials can be adapted for repairs when options are limited.

Applying hot mixed mortar and building up a core arch to hold the inner and outer arch together.

Although we were working very hard, and staying up late to mind the kiln, we were well fortified by the excellent Cypriot food and wine. It kept our strength and spirits up, meaning we could finish the repair work and return home in time for Christmas, tired but happy.

The final state of the arch after a week, amazing right!?

While we were in Cyprus, we were working with local builders. They were interested in re-discovering the methods of hot-mix mortar preparation repair once common across Europe, which are currently enjoying a revival in Scotland.

The team celebrate a job well done

Want to find out more about hot-mix mortar? We have published several relevant publications that available to download for free.